Air lime has been used for thousands of years by different civilisations and on every continent, with beautiful vestiges found in Syria, Egypt, China, India and Europe, to name but a few.

From ancient times through to the last centuries, lime was used in construction for all sorts of masonry, rendering and decorative finishes. Today, these creations remain an invaluable resource through their remarkable durability and beauty.

Lime comes from limestone, which is one of the most abundant minerals on the surface of our planet. Every region had its specific formula for using lime (depending on its culture, building systems, etc.), proving that lime could be adapted to different building projects — houses, circuses, arenas, theatres, bridges, aqueducts, spas, piping systems and so on — and meet the demands of specific uses.

Production methods did not change much right up to the 19th century. Despite traditional production methods being used over a long period, craftsmen used their expertise to develop specific procedures for producing high-quality materials.

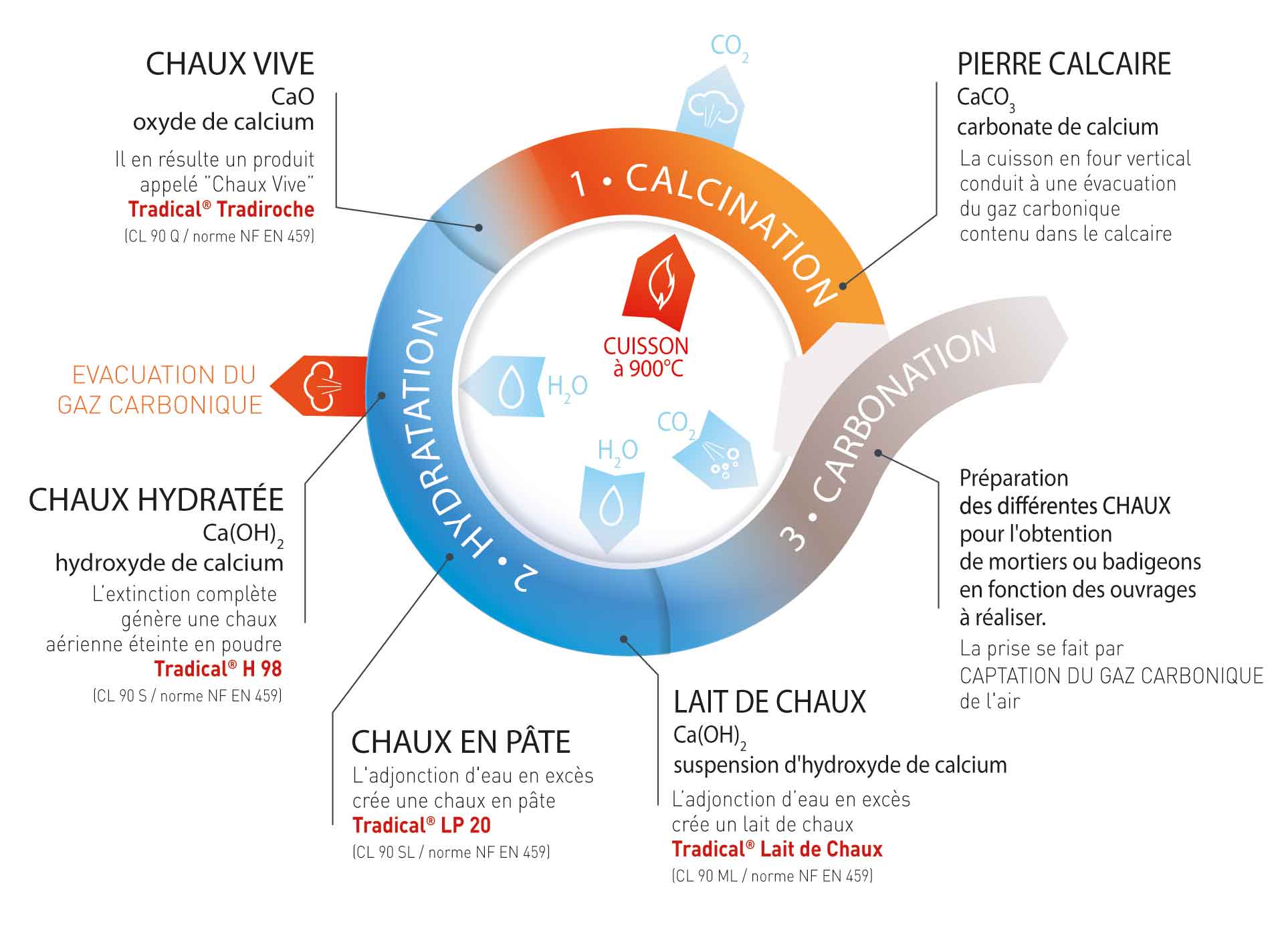

The basic production method was always the same: limestone was heated in a wood-fuelled kiln over several days. The shape of the kiln evolved over time to enable better temperature control, the ideal temperature being 750°C. However, as these kilns were rather simply engineered, the results obtained from firing varied.

The importance of slaking

To compensate for these varying results which influenced the quality of the final product, this quicklime was always hydrated in a slaking tub. By immersing the quicklime in special pools, sedimentation would occur over several months to obtain the right quality and guarantee the consistency of the lime’s properties.

Lime breaks down in water and settles in different layers. Letting the paste mature enabled any firing inconsistencies to be eliminated by hydrating the dead burnt lime and giving under-burnt lime the time to sediment…